Post by drfakoo on Sept 16, 2008 18:54:46 GMT -5

It was a hot July afternoon, during one of our weekend trips. My buddy Cesc and me were having a cold beer, admiring the mountains, when suddenly this conversation came out:

.-Me: You know buddy, I would like so much to learn welding...

.-Cesc: Well I know a little bit, but if we have to learn seriously, let´s go for it !!!

We continued drinking our beers quietly, also admiring our Toys, and I had no better idea than saying... :

I would also like very much to have a new front bumper, but there is nothing exactly what I want here in Spain. I have it all on my mind. It also must have a winch, off course...

Suddenly, without saying any word, we had a deep eye contact (not a gay one...), so we realized that both of us were thinking the same.

.-Cesc : And what about if we fab them

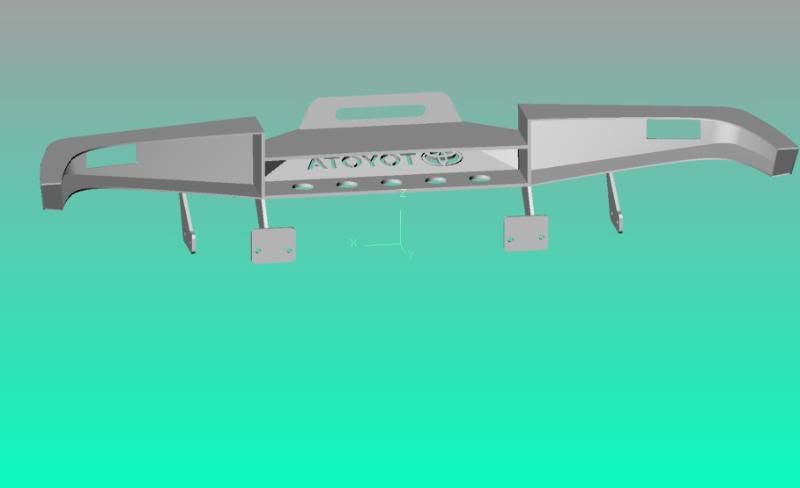

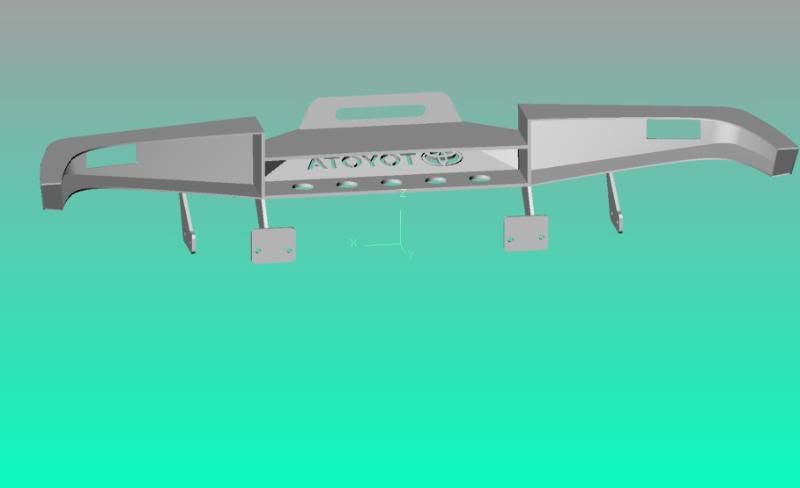

The next weekend we sat in front of Cesc´s PC and started drawing some ideas ( unfortunatelly, we have more for the future ...;-)

For me, it was very clear that the bumper had to start inspired on Front Range Off Road bumpers style (unfortunately not sold in Spain and very expensive to import...).

We took of the original front bumper and started taking measurements and putting them into the pc.

After many, many, many hours, and when I say many, means that we sat many ours in front of the pc, finally we had the final design.

Cesc take care of the technical part, calculous, structures, drawing, etc...

Meanwhile I sat next to him, with my stupid face, looking how this guy worked with CAD.

From time to time I opened my mouth just to say:

.-Me: Can we round this edge

.-Me: Can we move the hole

.-Me: Are you sure this is going to fit into our rigs Sometimes computers make mistakes... (I was wrong...).

Sometimes computers make mistakes... (I was wrong...).

On the next step we got all metal pieces cut by laser. 8 mm thick for the center box, and 4 mm thick for the wings of the bumper.

After we got all the pieces of the puzzle, the funny part of the project started.

Here was where I got to support my buddy with something more than ideas. So, lets start to weld.

My brother Willy came to give us some advices (he is an expert welder).

On date and at the exact hour I was prepared to start my adventure.

I spent the previous, night watching weld tutorial videos. This was like watching porn movies, without having any real sex experience yet... ;-)

After first indications, my brother gave to me to pieces of metal to feel the welder.

Seems to be that they liked the welds, cause they directly gave me part of the bumper to weld.

So after that I was officially baptized as the welder of the team ;-)

Professional welders, please don´t puke !!! Hope they are not so bad for a newbee ...

Some pieces were pre-curved before positioning them, as for example the corner plates of the bumper.

Cesc, fabbed a stamp for those pieces. (He is a proffesional matrixer ).

I´m going to explain the funny story about our brand (we are not pros, and this is just a hobby for us).

While we were designing the bumper, we had the strong feeling, that we liked so much what we were drawing.

And Cesc commented: Man !!! this will look like a pro bumper, we should have our own brand, hahahahahahahaha !!!!

Me.- You are not going to believe me, but I have the name.... FatMouse !!! A few days before while I was smoking a tunning cigarette, at night , watching the stars; I had a vision...

If I sometime create a company (don´t missunderstand me, I am a surgeon, way to far related to the off road industry) it will be called FatMouse.

.-Cesc: Man I like the name...FatMouse Off-Road !!! From today and on every thing we fab for our trucks, will have our own brand. We were just kidding ...

Five minutes later Cesc gave the order to the pc to draw the Fatmouse brand on our bumpers, hahahahahahahahahahaha.

And this is the story about our brand.

So, kids... Don´t smoke !!!! ;-)

Slowly, pieces were forming the bumper, and somebody was loosing to much saliva ....

Cesc and Willy working on the bumper...

Finally this started, to seem a bumper...

Serial production !!!

Thanks to Cesc, we had all machinery and tools we needed.

Watch video:

es.youtube.com/watch?v=KZCc5qRaOy0

Detail of the corner light support.

We decided to do some mods, during the fabrication. We put this piece of perforated metal sheet to hide the radiator and lines...

We added a reinforcement to the bumper, cause we had nothing better to do , hahahaahahahahahahaha !!!!!!

Final adjustments !!!

We went out to the street to admire it with day light !!!

Will it resist

We rounded edges.

This is a detailed picture of the holes we made, to fit a cut-off for the positive of the winch.

After we polished all the details on the metal, we applied epoxy putty with little alloy fragments in it, to correct imperfections.

After, I learned that I don´t have to apply so much putty on the bumper... God Damn it !!! This putty became so hard !!!! Hahahahahahahaha !!!!

We finished !!!!

Now to the painter ...

Satisfaction faces !!! Nothing like creating with your own hands, while spending a grate time !!!

After we got the bumpers from the painter, we mounted the winch to the bumper, corner lights and cut-off.

We turned the solenoid box 180º, to let the winch plugg free (we thought the connector was on top of the box, but model was changed) not a big problem at all.

Detail of the corner light mount.

Before fitting the bumper, we cut part of the inner plastic fenders, and trimmed the metal sheet under the lights.

And this is the final result !!!

We also fabbed a new cb antenna mount.

Soon I will put more pictures of Cesc´s Toy. It was dark for him and pictures were crap...

Hope you like it.

Feel free to criticize !!!

This is not the end... soon we will fab something new hehehehehehehehehee !!!!

To be continued ...

Thanks for reading.

Cheers !!!

Facu

;-)

.-Me: You know buddy, I would like so much to learn welding...

.-Cesc: Well I know a little bit, but if we have to learn seriously, let´s go for it !!!

We continued drinking our beers quietly, also admiring our Toys, and I had no better idea than saying... :

I would also like very much to have a new front bumper, but there is nothing exactly what I want here in Spain. I have it all on my mind. It also must have a winch, off course...

Suddenly, without saying any word, we had a deep eye contact (not a gay one...), so we realized that both of us were thinking the same.

.-Cesc : And what about if we fab them

The next weekend we sat in front of Cesc´s PC and started drawing some ideas ( unfortunatelly, we have more for the future ...;-)

For me, it was very clear that the bumper had to start inspired on Front Range Off Road bumpers style (unfortunately not sold in Spain and very expensive to import...).

We took of the original front bumper and started taking measurements and putting them into the pc.

After many, many, many hours, and when I say many, means that we sat many ours in front of the pc, finally we had the final design.

Cesc take care of the technical part, calculous, structures, drawing, etc...

Meanwhile I sat next to him, with my stupid face, looking how this guy worked with CAD.

From time to time I opened my mouth just to say:

.-Me: Can we round this edge

.-Me: Can we move the hole

.-Me: Are you sure this is going to fit into our rigs

Sometimes computers make mistakes... (I was wrong...).

Sometimes computers make mistakes... (I was wrong...).On the next step we got all metal pieces cut by laser. 8 mm thick for the center box, and 4 mm thick for the wings of the bumper.

After we got all the pieces of the puzzle, the funny part of the project started.

Here was where I got to support my buddy with something more than ideas. So, lets start to weld.

My brother Willy came to give us some advices (he is an expert welder).

On date and at the exact hour I was prepared to start my adventure.

I spent the previous, night watching weld tutorial videos. This was like watching porn movies, without having any real sex experience yet... ;-)

After first indications, my brother gave to me to pieces of metal to feel the welder.

Seems to be that they liked the welds, cause they directly gave me part of the bumper to weld.

So after that I was officially baptized as the welder of the team ;-)

Professional welders, please don´t puke !!! Hope they are not so bad for a newbee ...

Some pieces were pre-curved before positioning them, as for example the corner plates of the bumper.

Cesc, fabbed a stamp for those pieces. (He is a proffesional matrixer ).

I´m going to explain the funny story about our brand (we are not pros, and this is just a hobby for us).

While we were designing the bumper, we had the strong feeling, that we liked so much what we were drawing.

And Cesc commented: Man !!! this will look like a pro bumper, we should have our own brand, hahahahahahahaha !!!!

Me.- You are not going to believe me, but I have the name.... FatMouse !!! A few days before while I was smoking a tunning cigarette, at night , watching the stars; I had a vision...

If I sometime create a company (don´t missunderstand me, I am a surgeon, way to far related to the off road industry) it will be called FatMouse.

.-Cesc: Man I like the name...FatMouse Off-Road !!! From today and on every thing we fab for our trucks, will have our own brand. We were just kidding ...

Five minutes later Cesc gave the order to the pc to draw the Fatmouse brand on our bumpers, hahahahahahahahahahaha.

And this is the story about our brand.

So, kids... Don´t smoke !!!! ;-)

Slowly, pieces were forming the bumper, and somebody was loosing to much saliva ....

Cesc and Willy working on the bumper...

Finally this started, to seem a bumper...

Serial production !!!

Thanks to Cesc, we had all machinery and tools we needed.

Watch video:

es.youtube.com/watch?v=KZCc5qRaOy0

Detail of the corner light support.

We decided to do some mods, during the fabrication. We put this piece of perforated metal sheet to hide the radiator and lines...

We added a reinforcement to the bumper, cause we had nothing better to do , hahahaahahahahahahaha !!!!!!

Final adjustments !!!

We went out to the street to admire it with day light !!!

Will it resist

We rounded edges.

This is a detailed picture of the holes we made, to fit a cut-off for the positive of the winch.

After we polished all the details on the metal, we applied epoxy putty with little alloy fragments in it, to correct imperfections.

After, I learned that I don´t have to apply so much putty on the bumper... God Damn it !!! This putty became so hard !!!! Hahahahahahahaha !!!!

We finished !!!!

Now to the painter ...

Satisfaction faces !!! Nothing like creating with your own hands, while spending a grate time !!!

After we got the bumpers from the painter, we mounted the winch to the bumper, corner lights and cut-off.

We turned the solenoid box 180º, to let the winch plugg free (we thought the connector was on top of the box, but model was changed) not a big problem at all.

Detail of the corner light mount.

Before fitting the bumper, we cut part of the inner plastic fenders, and trimmed the metal sheet under the lights.

And this is the final result !!!

We also fabbed a new cb antenna mount.

Soon I will put more pictures of Cesc´s Toy. It was dark for him and pictures were crap...

Hope you like it.

Feel free to criticize !!!

This is not the end... soon we will fab something new hehehehehehehehehee !!!!

To be continued ...

Thanks for reading.

Cheers !!!

Facu

;-)

But like already said the shipping to the states would be murder.

But like already said the shipping to the states would be murder.